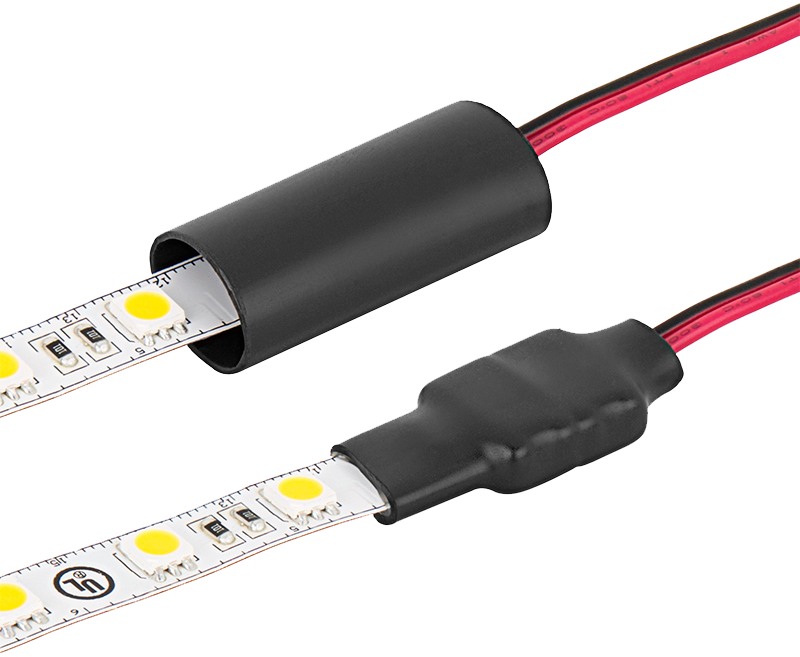

As the name suggests, heat shrink tubing is a tube that shrinks when exposed to heat. It comes in a range of different materials suited for practically any environment. It's the ideal solution for cable connecting, management and repair.

Benefits of using heat shrink tubing

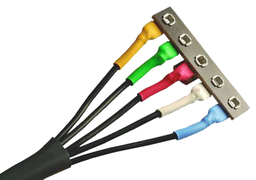

As it goes over cables and wires, it's mainly used as a protective cover. It completely seals off and protects the covered area from the environment. Heat shrink can also serve a cosmetic purpose by using it to bundle wires together or color-code specific wires.

The main uses of heat shrink:

Seal off the ends of braided sleeves

Visually improve the look of cables in exposed areas

Insulate cables in a high-temperature environment

Improve abrasion resistance

Improve the chemical resistance of cables

Color code cables for identification purposes

Relieve the strain of stretching and compression

Protect cable splices from dust and moisture

Flame retardant

Materials and types of heat shrink tubing

The most common material for heat shrink tubing is polyolefin. That is due to the fact that it can resist high temperatures up to 135°C.

PVC based heat shrink is also widely used but it can usually only withstand temperatures up to 105°C. The popularity of PVC heat shrinks comes from its other great features and their price is up to 50% cheaper than polyolefin heat shrinks, depending on the product.

PVC heat shrinks also have better physical attributes than polyolefin products. They have better tensile strength and abrasion resistance. When it comes to cosmetic features, PVC wins again. It can offer much brighter and more vibrant colors plus their clear tubes have better clarity.

Some heat shrinks feature an adhesive lining. Usually, they are regular polyolefin shrinks that have been added an inner adhesive liner. The way it works is that the shrinking temperature of the tube and the melting point of the adhesive are the same. When the tube shrinks, the adhesive flows and fills all the voids on the underlying material and creates a moisture and particle-free environment.

Heat shrinks actually come in a wide range of materials but most of them are meant for difficult non-standard environments. The most common ones are Viton, Neoprene, PTFE, PVDF, FEP and silicon rubber.

How to use heat shrink tubing

The most common questions about heat shrink tubing are what size heat shrink tubing do I need and how to heat shrink tubing. Answers to these questions and more valuable know-how on using heat shrink tubing are provided to you in these following steps:

The most common questions about heat shrink tubing are what size heat shrink tubing do I need and how to heat shrink tubing. Answers to these questions and more valuable know-how on using heat shrink tubing are provided to you in these following steps:

Step 1. Measure the diameter and length of the cable or wire

The correct heat shrink tubing is chosen based on the object it's applied to. Get an accurate measurement of the cable or wire you're working with.

Step 2. Determine the conditions the tubing will be exposed to

As mentioned before, there's a big variety of shrink tubes available for different requirements. For example, if you're working with a high-temperature and high-moisture environment, you have to be certain that the tubing can withstand that and offer the required protection to the cables or wires.

Step 3. Choose tubing with the right shrink ratio and wall thickness

The shrink ratio is a pretty straightforward value. For example, when a tube has a 2:1 ratio, it means that it has been expanded two times its initial size. When using a 2cm tube with a 2:1 ratio, it will shrink to 1cm when heated.

When working in a size-sensitive environment, you have to consider the shrunk wall thickness of the tubing. The wall thickness increases when the tube is shrunk so look at the technical data for the exact measurement.

Sep 4. Calculate the length of the tubing

Although the loss in length is not very big, usually between 5% and 15%, it can be noticeable. Look at the technical data of your shrink tubing and make sure you leave enough excess tubing to cover the whole length of your wire or cable.

Step 5. Apply and shrink the tubing

Slide your tubing or the wires. To get a more even application, you can suspend the wire or cable.

When your tubing and wire or cable are in position, start applying heat. A heat gun works best but you can also use a small butane torch. Move your heat source back and forth along the length of the tube, making sure you don't stay in one spot for too long and damage the wire or cable underneath.